SinoScan solved capacity challenges during a growth period

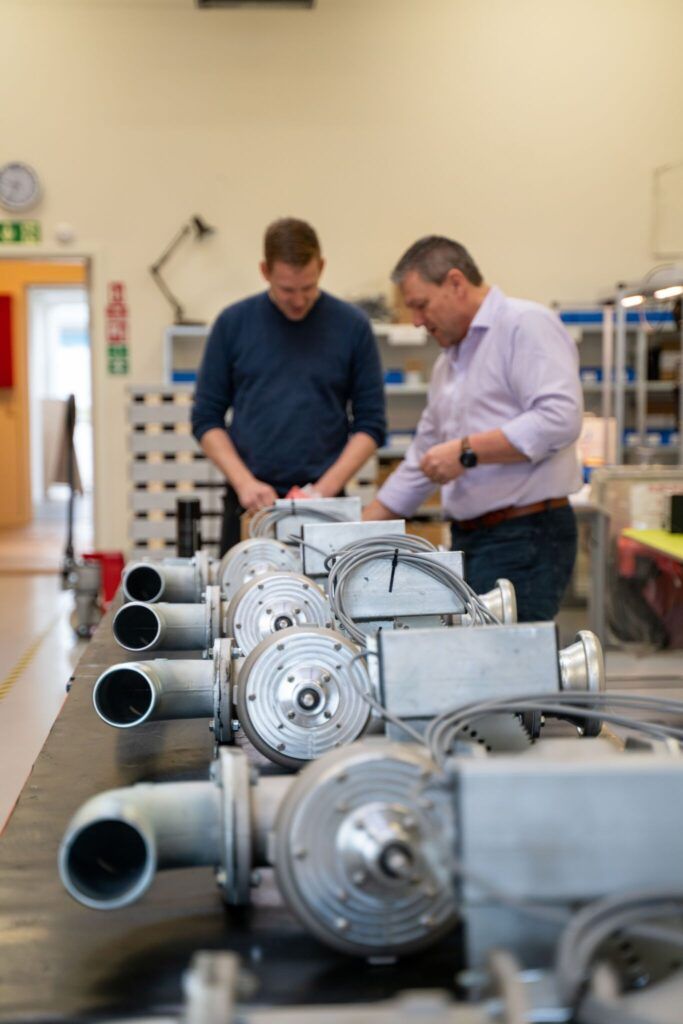

Outsourcing production became part of the solution, and SinoScan became the external manufacturer of the turbine unit.

A better product, stable delivery, and lean production

Fasterholt, a leading manufacturer of irrigation machines in the market, faced capacity challenges and recruitment issues during a period of intense growth. Their goal was to optimise the production process and maximise the utilisation of their core competencies.

A solid collaboration began with

a strong vision

Fasterholt initiated a lean-optimization process to address capacity challenges and recruitment issues, as increased growth required optimisation of their production to maintain the delivery of their irrigation machines.

At the same time, Fasterholt saw an opportunity to optimise their pump unit to the same extent by outsourcing production.

SinoScan assisted throughout the development process to ensure the design, quality, and production of the new unit.

Design

Engineering

Manufacturing

Customised Services

Establishment of Production and Assembly Line

Project management

Deliveries

Outcome

Fasterholt improved production capacity through their lean project by outsourcing pump unit production to SinoScan. This strategic move solved capacity challenges and met increased demand. The collaboration with SinoScan ensured that high-quality standards were maintained while production was streamlined as part of the lean strategy.

The successful combination of increased capacity and streamlined production demonstrates the value of Fasterholt’s lean project, which integrates outsourcing to improve processes and reduce costs.

From bottleneck to optimised production

A fresh start provided the opportunity to optimise both the production process and the product.

By outsourcing their pump unit, Fasterholt improved both design and production, allowing Them to deliver units of the high quality they are known for.

Quality control is a crucial part of the production and assembly of the pump unit. The consistent high quality is ensured by inspecting all components for defects and tolerances before they are assembled and shipped to Fasterholt.

This assures Fasterholt that the units they install in their irrigation machines always meet their standards, thereby minimising defects and reducing returns.

Focus on quality

From design to production setup, it has been crucial that the impellers, cast components, and assembly meet Fasterholt’s quality standards.

Prototypes and testing were essential parts of the development process, where various design options were tested and evaluated to find the optimal design and production method.

The pump must operate reliably for many years, so it has been crucial in the development process that all components are designed to withstand the loads they will encounter throughout their lifespan.

“

SinoScans’ combination of solid product development expertise and a well-established sourcing and assembly setup has been ideal for us.

We approached SinoScan with a design that still required significant product development. SinoScan has safely guided us through the development of a finished product, and on top of that, they have been able to handle component sourcing and product assembly.

I highly recommend SinoScan to anyone looking for a development partner, a manufacturing partner, or both.

Danny Hansen

Production Manager, Fasterholt